AXT-P line furnaces

KEY FEATURES

-

CONTROL

Thanks to highly advanced measuring and automation equipment, the furnace operates in fully automatic mode. -

COMPATIBILITY

Suitable for use with various types of boilers: water heating, steam, thermal oil and air heaters. -

FIRE EXTINGUISHING SYSTEM

The fuel supply hopper is equipped with a technological hopper cooling and extinguishing system, which ensures safe operation of the furnace. -

BUNKER CLOSING VALVE

The valve is designed to cut off the fuel supply system from the furnace and to reduce possible air intake during stopping procedure. -

HYDRAULIC FUEL SUPPLY

The furnace works with a fuel hopper, which feeds the fuel into the combustion chamber continuously and in the required amount with the help of hydraulic cylinders. -

GRATING

The grate is made of heat-resistant cast iron with a chromium content of up to 27%. Special holes are provided for efficient blowing of primary and recirculation flue gas into the fuel bed. -

O2 CONTROL

The furnace is equipped with an oxygen maintenance system that will ensure that complete and proper combustion products are formed. -

AIR VENTILTORS

Precise combustion air distribution allows for better combustion of biomass, thus reducing pollution. -

FLUE GAS RECIRCULATION

Part of the flue gas removed from the furnace is directed back to the furnace. The purpose of this flue gas is to cool the elements of the furnace masonry and grate. -

AUTOMATIC ASH REMOVAL

The automatic ash removal system allows you to quickly and easily remove ash from the combustion process.

KEY ELEMENTS

KEY ELEMENTS

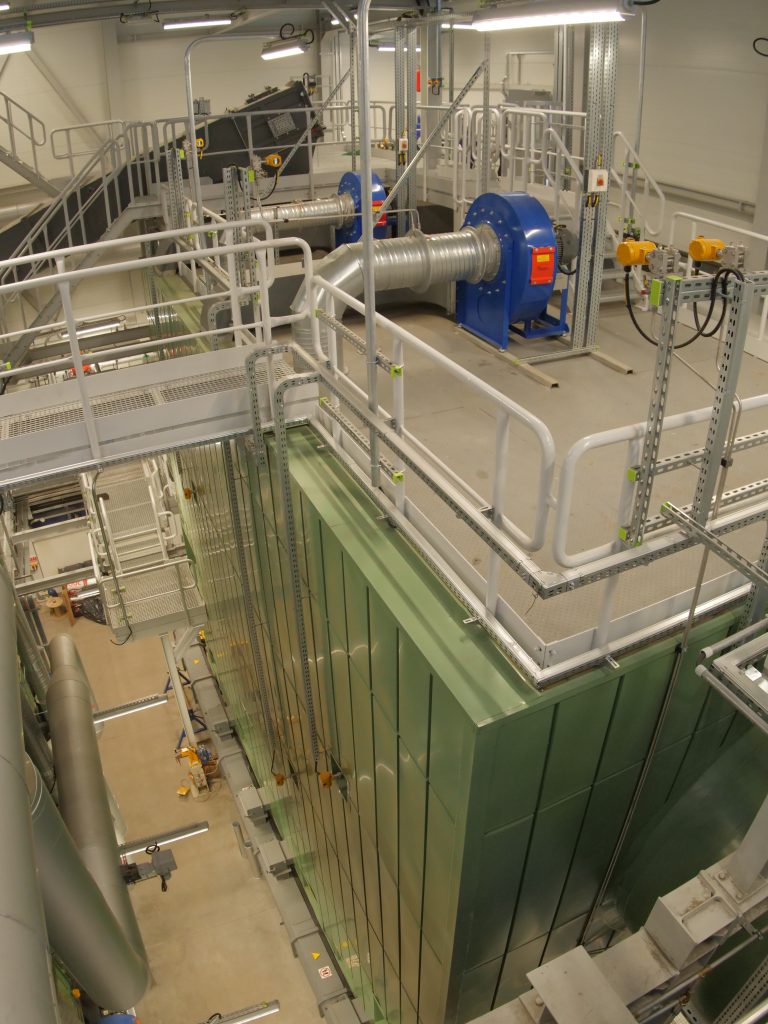

Furnace consists of a base frame, casing with thermal insulation, moving grate, fuel feeder with silo and it’s fire safety system, ash moving scrapers, air ducts with fans, hydraulic system for grate and fuel feeder. There are several inspection doors and sight glasses for convenient operation and maintenance of the furnace.

| Biomass | Biomass type |

| Stem wood | Deciduous and coniferous trees |

| Sawmill residues | Slab |

| Cuttings | |

| Saw dust (limited quantity) | |

| Shavings (limited quantity) | |

| Bark (limited quantity) | |

| Trees, timbers | Deciduous trees |

| Coniferous trees | |

| Mixed | |

| Logging residues | Vertices, branches, trunk trimmings, aboveground part of the stump |

| Small trees and whips | |

| Bush | |

| Wood of non-forest origin | Waste from landings, self-sowing and roadside cutting residues |

AXT-S line furnaces

KEY FEATURES

-

CONTROL

Thanks to highly advanced measuring and automation equipment, the furnace operates in fully automatic mode. -

COMPATIBILITY

Suitable for use with various types of boilers: water heating, steam, thermal oil and air heaters. -

FIRE EXTINGUISHING SYSTEM

The fuel supply hopper is equipped with a technological hopper cooling and extinguishing system, which ensures safe operation of the furnace. -

BUNKER CLOSING VALVE

The valve is designed to cut off the fuel supply system from the furnace and to reduce possible air intake during stopping procedure. -

HYDRAULIC FUEL SUPPLY

The furnace works with a fuel hopper, which feeds the fuel into the combustion chamber continuously and in the required amount with the help of hydraulic cylinders. -

GRATING

The grate is made of heat-resistant cast iron with a chromium content of up to 27%. Special holes are provided for efficient blowing of primary and recirculation flue gas into the fuel bed. -

O2 CONTROL

The furnace is equipped with an oxygen maintenance system that will ensure that complete and proper combustion products are formed. -

AIR VENTILTORS

Precise combustion air distribution allows for better combustion of biomass, thus reducing pollution. -

FLUE GAS RECIRCULATION

Part of the flue gas removed from the furnace is directed back to the furnace. The purpose of this flue gas is to cool the elements of the furnace masonry and grate. -

AUTOMATIC ASH REMOVAL

The automatic ash removal system allows you to quickly and easily remove ash from the combustion process.

KEY ELEMENTS

KEY ELEMENTS

Furnace consists of a base frame, casing with thermal insulation, moving grate, fuel feeder with silo and it’s fire safety system, ash moving scrapers, air ducts with fans, hydraulic system for grate and fuel feeder. There are several inspection doors and sight glasses for convenient operation and maintenance of the furnace.

| Biomass | Biomass type |

| Stem wood | Deciduous and coniferous trees |

| Sawmill residues | Slab |

| Cuttings | |

| Saw dust (limited quantity) | |

| Shavings (limited quantity) | |

| Bark (limited quantity) | |

| Trees, timbers | Deciduous trees |

| Coniferous trees | |

| Mixed | |

| Logging residues | Vertices, branches, trunk trimmings, aboveground part of the stump |

| Small trees and whips | |

| Bush | |

| Wood of non-forest origin | Waste from landings, self-sowing and roadside cutting residues |