Biomass storage and fuel supply systems

Fuel scraper transporters

*Depends on transporter configuration (length, rising part length, angle)

Fuel platforms

Vibrating mesh

Fuel levelers

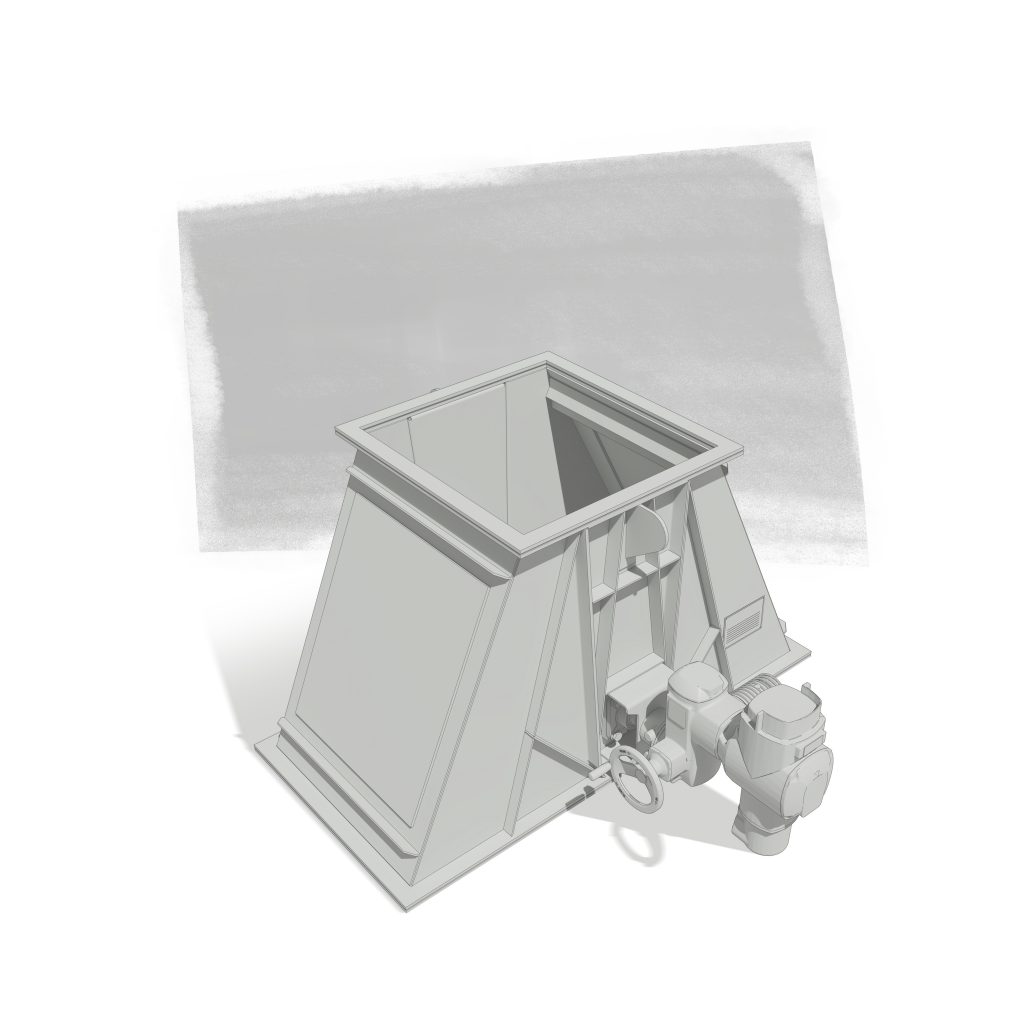

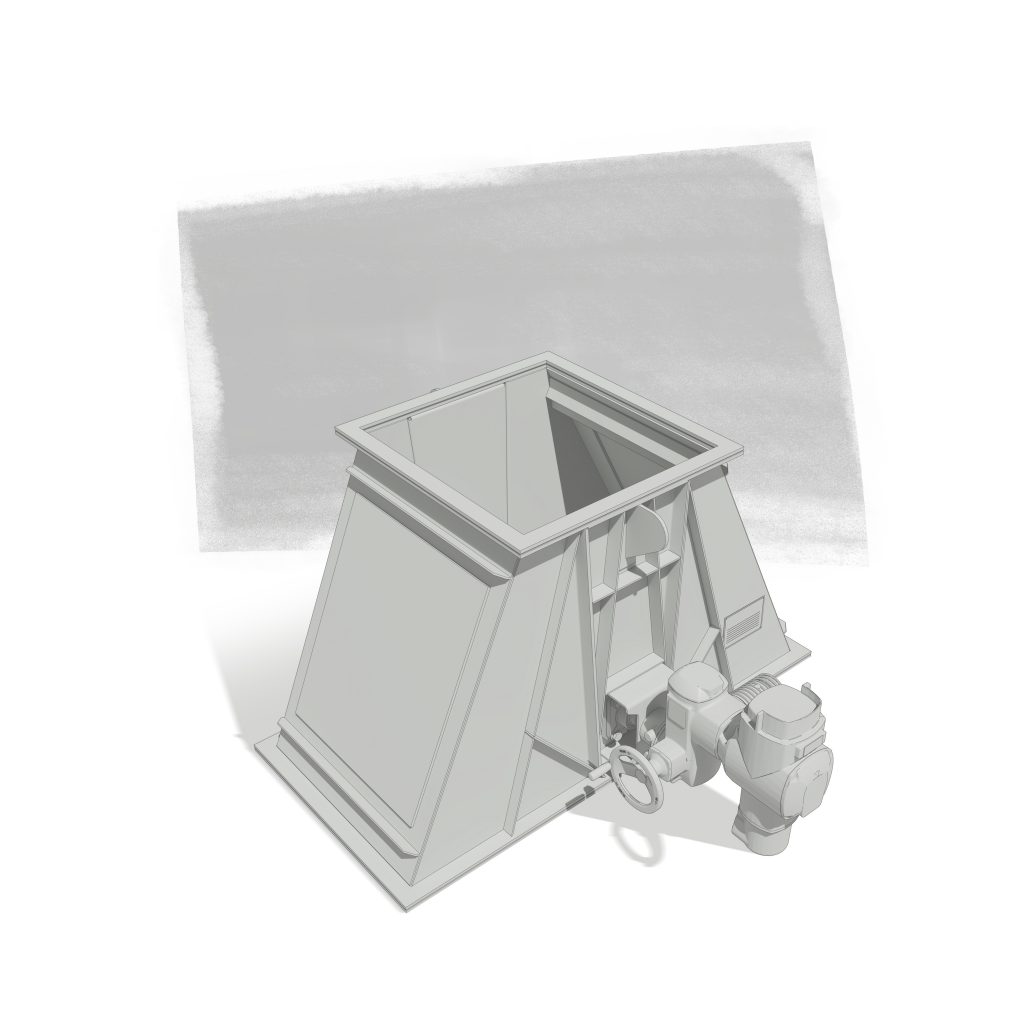

Fuel distributors

*Depends on transporter configuration (length, rising part length, angle)